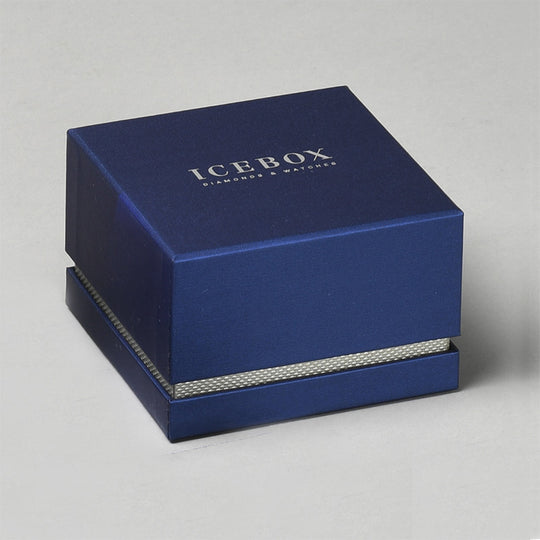

Rigid boxes are widely recognized as the go-to packaging solution for high-end brands due to their premium appearance and sturdy structure. They’re commonly used for luxury items such as premium shoes, jewelry, cosmetics, accessories and more. However, while these boxes exude quality and elegance, they can also be costly to produce.

For businesses, balancing the cost of rigid box production with maintaining its premium appeal is essential. In this article, we’ll explore practical strategies to reduce the cost of rigid boxes while ensuring they remain functional, visually appealing, and aligned with your brand image.

Understanding the Key Cost Factors of Rigid Boxes

To effectively reduce costs, it’s important to first understand what drives the cost of rigid boxes. Here are the main factors:

1) Materials

The materials used in the production of rigid boxes are a significant cost driver. The thickness and quality of the paperboard, wrapping paper, and any elegant finishings like metallic finishes or textured coatings all add to the expense.

2) Design Complexity

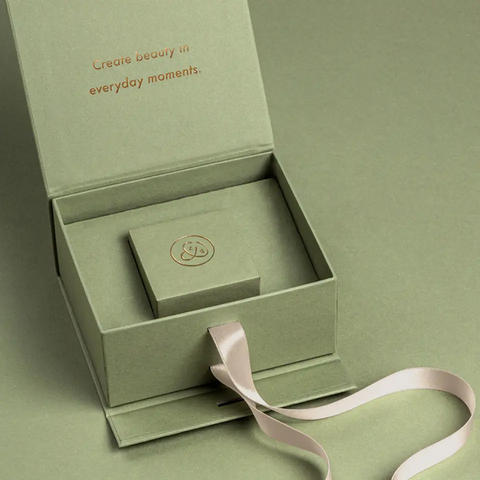

Custom shapes, special closures, and additional design features such as magnetic lids or ribbon ties increase production complexity and, therefore, costs.

3) Production Processes

Rigid boxes often involve manual processes, especially when they require hand assembly or multiple finishing touches. Processes like embossing, foil stamping, and UV coating also contribute to higher costs.

4) Volume

The cost-per-unit of a rigid box is directly impacted by the quantity ordered. Lower order volumes typically lead to higher per-unit costs due to setup expenses and inefficiencies.

5) Logistics

The dimensions and weight of rigid boxes influence shipping and storage costs. Bulky or heavy packaging can significantly increase logistics expenses, especially for international shipping.

By addressing these cost factors, businesses can find ways to make their packaging budgets more efficient.

Tips for Reducing the Cost of Rigid Boxes

1) Optimize Material Selection

One of the easiest ways to reduce costs is by optimizing the materials used. For example:

- Use thinner paperboard for products that don’t require heavy-duty protection.

- Explore alternative materials like recycled or FSC-certified paperboard, which can be more affordable while enhancing your brand’s sustainability image.

- Option for simpler wrapping papers or finishes. For instance, matte lamination is often more cost-effective than textured coatings or gloss finishes.

These adjustments not only reduce material expenses but also align your packaging with eco-conscious consumer trends.

2) Simplify Box Design

Simplifying the design of your rigid box can lead to significant cost savings.

- Standard shapes like rectangles or squares are more cost-effective to produce compared to custom or irregular shapes.

- Minimize the use of additional features such as magnetic closures, ribbons, or excessive inserts.

- Avoid overly complex branding elements, such as multi-layered embossing or intricate patterns, unless they are essential for your product’s identity.

Streamlined designs are not only more affordable but also quicker to produce, reducing lead times.

3) Increase Order Volume

Ordering larger quantities of rigid boxes can significantly lower the cost per unit due to economies of scale. Many suppliers offer discounts for bulk orders, which can offset the initial investment.

Work closely with your packaging supplier to plan your order quantities based on projected demand, ensuring that you’re not ordering excessive inventory but still benefiting from bulk pricing.

4) Reduce Production Complexity

Production processes can often be simplified to reduce costs:

- Automate manual tasks where possible to cut labor expenses.

- Combine production steps to streamline assembly and finishing processes.

- Focus on modular box designs that require fewer materials and simpler assembly.

For example, instead of a rigid box with a separate lid and base, consider a one-piece design with a magnetic flap.

5) Optimize Logistics

The dimensions and weight of rigid boxes can have a significant impact on shipping and storage costs:

- Explore flat-packed rigid boxes that are shipped in a collapsible form and assembled on-site.

- Minimize the size and weight of the packaging without compromising product protection.

- Partner with suppliers that offer integrated logistics solutions to simplify shipping coordination.

Efficient logistics not only save costs but also reduce the environmental impact of transportation.

The Role of Sustainability in Cost Reduction

Sustainability isn’t just about being environmentally friendly—it can also help cut costs. By choosing eco-friendly materials and processes, you can reduce waste and improve efficiency.

Examples of Sustainable Cost-Saving Measures:

- Use recycled paperboard or biodegradable materials for the rigid box structure.

- Implement designs that encourage reusability, allowing consumers to repurpose the box.

- Reduce material waste by optimizing cutting patterns during production.

Additionally, sustainable packaging resonates with consumers, particularly younger, environmentally conscious demographics. By aligning your packaging with these values, you can add brand value while cutting costs.

Case Studies or Real-World Examples

To better illustrate how these strategies work, let’s look at some examples:

- Example 1: A cosmetics brand reduced its packaging costs by switching from premium textured finishes to matte wrapping paper, achieving a sleek, minimalist look that appealed to its audience while lowering material expenses.

- Example 2: A high-end fashion brand transitioned to flat-packed rigid boxes for its e-commerce orders, saving on shipping and storage costs without compromising the unboxing experience.

These examples show how small changes can have a significant impact on costs while maintaining the perceived value of your product.

Conclusion

Reducing the cost of rigid boxes doesn’t mean compromising on quality or aesthetics. By focusing on material optimization, design simplicity, production efficiency, and sustainable practices, businesses can achieve cost savings while preserving the premium look and feel that rigid boxes are known for.

At Xinxiang Package, we specialize in providing cost-effective, high-quality rigid box solutions tailored to your brand’s needs. Our expertise in design, production, and logistics ensures that you can achieve your packaging goals without breaking the bank.

Ready to optimize your packaging costs without sacrificing quality? Contact Xinxiang Package today to explore our customizable rigid box solutions. Let us help you find the perfect balance between cost-efficiency and premium design for your products.